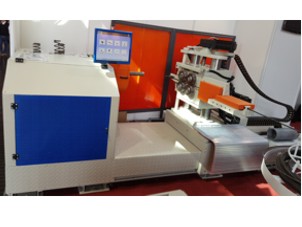

WEEM, CNC SPRING COILING MACHINES

only in the world which cover 90% type of springs

The new generation of CNC – SPRING MACHINES

-100% automatic spring coilers based on mandrel coiling.

This serie of CNC spring coilers are ideal for cylindrical, conical, torsion and double torsion springs and for making the straight wire pieces.

They are equipped with full automatic wire feeding in both directions and with wire cutting.

![]()

WEEM-xxxC latest technical solutions :

– servo drives, servo geared motors,

– CNC control with industrial PC computer, touch screen,…

– windows base software

– windows suroundings (hardware)

– touch screen

– network (TCP/IP)

NEW !!!

Now CNC machines can coil also tape springs with additional tools.

The new generation of servo CNC lathe machine WEEM-xxxC

– spring wire range: 1,0-20,0 mm;

– cutting wire in first and last coil – at 5 axses machines

– five/three servo controlled axes:

Coiling; Wire feeding; feeder box: moving left-right, up-down (5 axses), forward- backward (5 axses) .

All five axes- 100% programmable

Servo drives, servo geared motors made by Lenze

Hydraulic works: wire cutting, , holder of mandrel , holder of wire cutter

Motor works: wire catching (5 axses)

– Computer control, 17” LCD touch screen

– coiling compression & tension springs automatically (without extra trimming)

– Windows base software, easy programming

– unlimited number of programs

– remote servicing and update (internet)

– software covers upgrade of additional tooling (like cylinders for extra wire forming, holders, touch sensors,…)

– bending wire in one axes, but using extra parts like cylinders , a very complex wire forms could be made on the machine

Standard accessories:

– wire guides, catchers, knifes, straighteners, feeding rolls

– hydraulic power unit, external cutter

– software, mechanical and electric machine adaptation for bending wire (getting different wire forms)

Options:

– additional straighteeners

– mandrels

– tooling for double torsion springs

Our CNC WEEM-xxxC lathe spring coiling machines are very robust and strong machines with a long life time.

The handling is very easy and friendly. Software is made on the Windows-10 base.

Set up time is short.

The accuracy is very high because the every signal on the servo drives is controlled.

The bending wire programs are easy made by hand commands

Our WEEM-xxxC machines are number one in world according to price, possibilities, speed, accuracy and long life time.

The advantages of our new generation WEEM-xxxC CNC lathe spring coiling machine:

-3 or 5 servo axes

-Making compression, tension and torsion springs without extra trimming

-Very easy handling and fast setup time for new spring design

-Very high precision, accuracy and repetation

-One axes – wire bending machine

-Possibility using extra outputs (like pneumatic cylinders) and inputs, enable wire forming and wire bending in more axes

-Very strong mechanical construction

-Springs fall down not on the machine

-Very friendly software

|

5 Servo axes |

|

WEEM-85C |

WEEM-125C |

WEEM-145C |

WEEM-205C |

|

3 Servo axes |

WEEM-43C |

WEEM-83C |

WEEM-123C |

WEEM-143C |

WEEM-203C |

| max. cutting wire |

4,2 mm |

8,2 mm |

12,2 mm |

14,2 mm |

20,0 mm |

| max. coiling wire |

6 mm |

10 mm |

14 mm |

16 mm |

30,0 mm |

| max. spring diam. |

140 mm |

140 mm |

150 mm |

200 mm |

250 mm |

| Max. spring length |

800 mm |

1.700 mm |

1.700 mm |

1.600 mm |

1.600 mm |

| max. length of legs |

250/5.000 mm |

320/5.000 mm |

350/5.000 mm |

350/5.000 mm |

500/5.000 mm |

| speed of coiling: |

0 – 350 rpm |

0 – 320 rpm |

0 – 320 rpm |

0 – 320 rpm |

0 – 250 rpm |

| wire cutter: |

Pneumatic |

hydraulic |

hydraulic |

Hydraulic |

Hydraulic |

| weight ca. |

1.100 kg |

1.800 kg |

2.900 kg |

3.400 kg |

6.000 kg |

| dimension H*W*D |

1200 * 2250 * 600 |

1700 * 3700 * 900 |

1300 * 3900 * 1600 |

1700 * 4200 * 1800 |

1800 * 5500 * 1800 |

| mandrels: |

71 pieces |

85 pieces |

93 pieces |

97 pieces |

80 pieces |

| Pipes-wire guides |

4 pieces |

8 pieces |

10 pieces |

10 pieces |

10 pieces |

| knifes: |

2 pieces |

2 pars |

2 pars |

2 pars |

4 pars |

| feeding rolls: |

2 sets |

3 sets |

3 sets |

4 sets |

4 sets |

| wire catcher: |

1 set |

1 set |

1 set |

1 set |

1 set |

| straighteners: |

1 piece |

1 piece |

1 piece |

1 piece |

1 piece |

|

Other standard parts (included in the price): |

|||||

|

-hydraulic power unit |

|||||

|

Extra parts: |

-extended bed |

||||